| >next> Foto Documentation August 2015 |

Understanding Morandi - The Post-Stressed Conrete Cable Stays

|

Grateful for any comments (please scroll down to page footer).

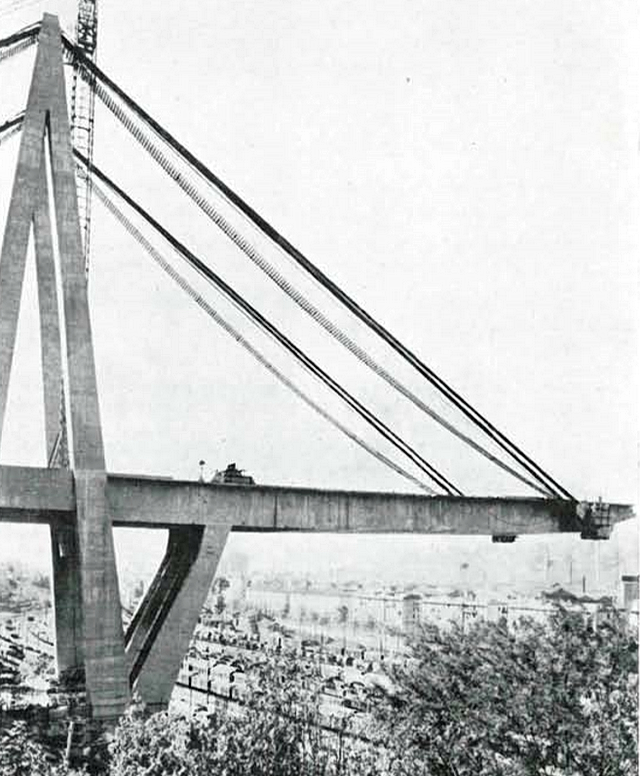

Riccardo Morandi, the lead engineer of the Polcevera Viaduct, was one of the rare engineers to employ post-stressed concrete cable stays in bridges. It made me curious to learn about the reasons, and to learn how the system functions. First look on Pylon 9:

|

| Image 1 (Hasenjäger 2015): Pylon 9 - The cable stay consists of two distinct stays in their lower part which merge half way up towards the tower. |

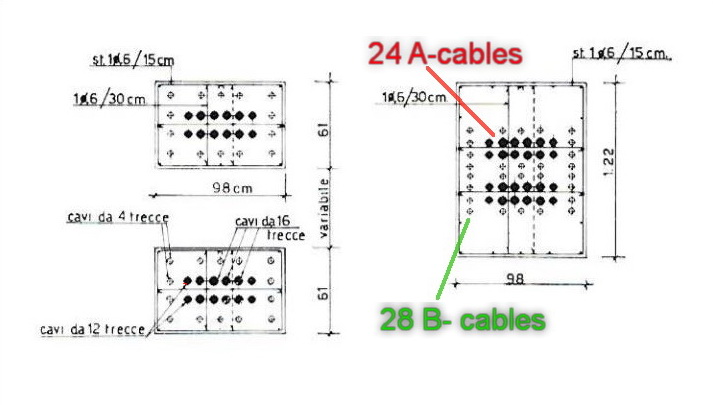

Let us consider two cross-sections of those cable stays. Observe two kinds of cable bundles: A and B-types. The 24 inner A-type bundles consist of 12 parallel independent cables each, while the 28 outer A-type bundles consist of 4 parallel independent cables each.

|

| Image 2 (Morandi 1968): Two cable stay cross-sections. 24 A-type bundles of 12 cables each and 28 B-type bundles of 4 cables each . |

In the drawing above, the right cross-section is located somewhere in the upper part of the cable stay, towards the top of the pylon. The cross-section to the left is located in the lower part: In fact there are two superimposed cable stay packs that merge further up. Adding complexity to the static system, esp. in the long run.

Also notice the cross-section drawings show cables of two different diameters: Thicker A-cables and thinner B-cables. Both have very different functions and assembly modes:

The stronger A-cables were first lined and tightened, supporting the weight of the box-type cantilever carriageway at their ends. So there was no concrete around them yet. Therefore, no precise Pre-stressing was possible at this point. This will be done in a next step with the B-cables, which I'll explain hereafter.

The photo below shows this construction phase: Two sets of 12 inner A-cables have been spanned, still without the concrete boxing around them, but already supporting the cantilever carriageway.

|

| Image 3 (Morandi 1968): Twenty-four bundles of raw A-cables supporting part of the cantilever deck, prior to concrete casting. |

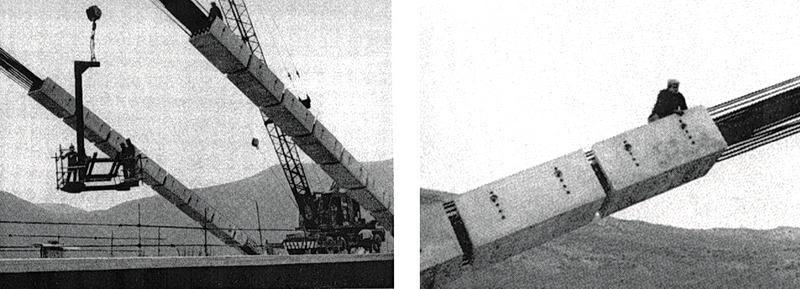

In a further construction step, a concrete box has been poured in a cast supported by the inner A-type bundles of cables. Image 4 below most likely show a more evolved version of such a process, during construction of Carpineto viaduct around 1977. As the images below show, appended prestressed concrete casts are being used. In Genova, most likely external in-situ casting was employed (confirm?).

|

| Image 4 (Sala 2016): Precast concrete box elements are being attached to the main A-cables of Carpineto Viaduct around 1977 . The elements will later be filled with concrete and then post-stressed with additional B-cables. |

The 28 outer B-type bundles of cables have been inserted once the concrete box beam was mostly completed as the image below shows. Note that the (green) B-type bundles are not yet tensioned (loose ends), while the (red) A-type bundles support the weight of the bridge deck.

|

| Image 5 (unknown source): A worker winds tape around a sheath through which a B-type bundle (4 cables each, colourized in green) is routed. At this point, those B-type bundles are not tensioned nor connected to the bridge structure yet. Separated by a sheet iron, a layer of six A-type bundles (colourized in red) are already tensioned, and fully support the bridge deck. The void inside the sheaths was later filled with special concrete. However, it appears that this process was not carried out with enough care, leaving void caves at some points. Note the guard-rail on the far right, whose presence indicates that tensioning of the B-cables takes place once the final load of the bridge has been mosty reached. |

The outer B-cables were mechanically post-stressed to keep the concrete girder under constant compression. In fact, Morandi thought that applying major tension to the outer B cables and less tension to the inner A-cables would reduce mechanical wear and tear of the "main" A-cables. The tension applied to the outer B-cables should be just tight enough to just support the maximum bridge load, including road vehicles. Remember that only the tension of the outer B-cables could be precisely calibrated during construction phase.

However, a major problem arose: After the concrete box around the cables was constructed, the resulting sag and weight induced lengthening changed the already fixed effective (=straight) length. Therefore, the carriageway was not (and would never be) horizontally well-levelled. In the later years.

In addition to this, a series of further challenges needed to be taken into account, some of them could have contributed to the recent bridge failure:

- Because the post-stressed concrete beam is very thin in relation to its length, and also because of the noticeable sag (see side views of the bridge), the compression that could be applied to it was rather limited. Morandi knew this very well: Applying too much compression through the B-cables would have resulted in non-controllable destructive effects.

Morandi has chosen the B-cables to be tensioned for a low compression range in the beam from nearly zero compression (at fully loaded carriageway) to a rather low positive value (when empty carriageway). - In other words: From the very beginning, the stays were not compressed as tight like conventional pre-stressed beams (i.e. of bridges). Their positive attributes therefore do not fully apply to Morandi's prestressed cable strays.

- Adding to this, during years of operation, highly tensioned cables are inevitably exposed to the phenomenon of relaxation, a loss of tension occurs. Therefore, also compression in the concrete stray decreases over time until reaching a critical point, total relaxation.

- Unfortunately low/zero longitudinal compression in a thin beam makes it prone to cracks, rapid degeneration and intrusion of water. It is likely pylon 11 reached this state before it was strengthened.

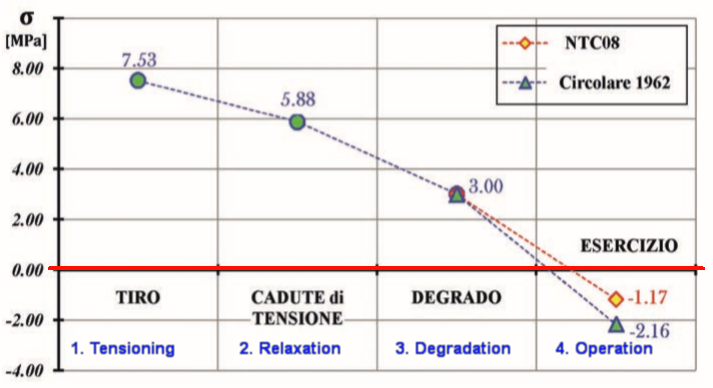

- The similar Carpineto Viaduct, built 10 years after the Polcevera Viaduct, suffered the problem of total relaxation as well, and was therefore thoroughly assessed and modelled (FEM) around 2013 by Della Sala et al.

Image 6 (Sala 2016 - modified to include English translations): Longitudinal compression in concrete post-stressed stay beam of similar Carpineto Viaduct. After initial tensioning in 1977 compressoin was set to 7.53MPa (77kg/cm²), which decreased more than half to around 3MPa until 2013. Under heavy load operation, the longitudinal compression would fall below zero, resulting in rapid degeneration and putting stability at risk. - Because the steel cables are bonded to the surrounding concrete, small cracks in the concrete inevitably lead to corrosion and additional wear.

- Because the cables can not be inspected as they are immersed in concrete, corrosive effects and single wire strand failure can not be detected.

In more modern designs, to enable constant monitoring, cables are electrically insulated so that single wire failures can be detected by changes of electric resistance of the cable. - Neither can the current compression in the concrete be measured easily.

- So both low tension and high tension need to be avoided in the concrete beams, and therefore a very wise range of post-stressing forces to be determined and applied during planning and construction, with possible re-calibrations later.

-

Because of steel relaxation and concrete viscosity, cable tension needs to be monitored in adequate intervals and, if necessary, re-calibrated. Unfortunately, neither effective monitoring nor re-tensioning is possible in the Genova design. The lack of precise, thorough and continuous monitoring possibilities (corrosion, wire strand failures, concrete compression) is not a helpful feature and may lead to unobserved critical degeneration.

Around 1993 pylon 11 received twelve additional external reinforcements cables to mitigate some of the above issues:

|

| Image 7: Pylon 11 - External reinforcement cables installed 1992-1994 (Hasenjäger 2007) |

Several challenges arose:

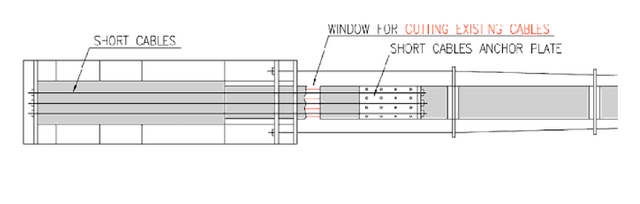

One major problem was that the tension applied to those additional cables should not increase the total combined compression of the thin concrete beam. Applying additional pressure would have been likely to damage the thin concrete beam structure. The successfully applied solution could be summarized as extremely complex: It consisted in cutting a section of the old concrete beam to also cut the old cables inside, while subsequently applying more tension to the new external cables.

|

| Image 8 (Malverde 2010): Pylon 11 - Additional reinforcement cables anchoring, cutting of existing cables. |

Concluding postscript:

I examined a number of articles about structural analysis and repair of Morandi type bridges, by different authors and Riccardo Morandi himself.

Riccardo Morandi gave three main reasons for the Polcevera concrete cable stay choice:

- To create a rigid bridge frame, consisting pylons (interlaced A-Antennas and V pylons), cable stays and the bridge deck. This would also reduce vertical movement of the cantilever bridge deck on changing (traffic) load and therefore reduction of torsion at its fixed end.

- To lower stress on the inner A-cables

- To protect the steel cables from meteorological and chemical effects

It could be interesting to observe that most other authors give rather different explanations why Morandi might have chosen this particular design. This diverging spectrum may be an evidence that there might not be a substantial rational argument in favour of the concrete-cable stays design when considering its draw-backs.

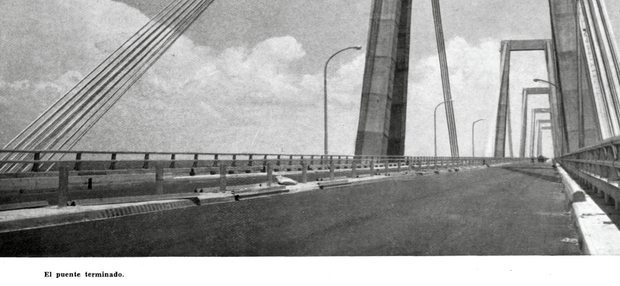

It must be noted that the cable stays of the very similar Lake Maracaibo bridge in Venezuela are not poured into a concrete beam.

|

| image 9 (Casado 1962): Maracaibo Bridge in Venezuela after completion in 1962. The bundled cable stays are not poured into concrete beams. |

|

| Image 10 (Casado 1962): Maracaibo Bridge in Venezuela after completion in 1962. The bundled cable stays are not poured into concrete beams. |

This is even more interesting when considering that the Maracaibo bridge (1957-1961) has been conceived five years before the Polcevera (1962-1966) bridge.

Morandi must have decided to abandon the simple steel cable layout around 1962 in favour of the more complex post-stressed concrete beam design.

by Kristian Hasenjäger

Last updated: December 15, 2021:

* Added image 5

* Changed from "A-type cables" to "A-type bundle of cables" to make more evident that 12 (A) and 4 (B) independent cables form one A/B type- bundle.

* Casting of post-stressed beams most likely not realized using precast concrete boxes, modified text accordingly.

Bibliography

|

- Camomilla-Pisani-Martinez-Cabrera (1994) Repair of the stay cables of the Polcevera Viaduct in Genova

- Casado C (1962) Puente sobre el lago Maracaibo - Informes de la Construcci¢n Vol.15 n146

- Codacci Pisanelli (2001) The Bridge on the Wadi Kuf valley - Libya Rehabilitation and maintenance project

- Della Sala - Sabatello (2016) Viadotto strallato Carpineto I

- Hofacker H (1960) Die Maracaibobr?cke in Venezuela - Ausfuehrungsprojekt

- Malerba P.G. (2010) Managing Old Bridges - Bridge Maintenance, Safety - Management and Life-Cycle Optimization - Proceedings of the Fifth International IABMAS Conference - Philadelphi USA,11-15 July 2010

- Morandi R. (1969) SOME TYPES OF TIED BRIDGES IN PRESTRESSED CONCRETE

- Morandi R. (n.d.) Manuale di ingegneria civile Zanichelli-esac volume II

- Morandi R. (1968) Viaducto sobre el Polcevera en Genova Italia

- Morandi R. (1979) Durabilita-ponte

- Podolny W. (1977ca.) Construction and Design of Cable Stayed Bridges

| 3: Guest - 7.3 years ago | Aug 21, 2018, 8:13:18 AM |

| 2: System Admin - 7.3 years ago | Aug 19, 2018, 10:19:03 AM |

| 1: Guest - 7.3 years ago | Aug 18, 2018, 4:12:50 PM |